LEAN LEADER FORMULA

PEOPLE - PROCESS - EQUIPMENT

A TRANSFORMATIVE GUIDE TO HELP YOU GROW FASTER IN OPERATIONS AND MANUFACTURING

Reject the idea that you need decades to grow from operator to Director, because you don't

After almost two decades of working in manufacturing and operations, interactions with thousands of team members, and more than 300 interviews, I have created a breakthrough formula to help you grow using my triangle of success framework. This triangle includes People, Processes, and Equipment.Through powerful stories, experience-backed practices, and actionable tips, the first book in the series - Lean Leader Formula - People will teach you:

1. How to assess your starting point to build your growth plan from there.

2. How to create deeper bonds and connections with the people you work with.

3. How to communicate, train, and develop people around you, which can help you to become a great leader.

It doesn't matter where you are in your growth journey - an operator, technician, line leader, supervisor, or manager - The Lean Leader Formula will help you to have an immediate positive impact on your work relationships, and hence on your life too. It will guide you to make better decisions and become a leader everyone wants to have in their teams.

A GROWTH SEEKER

Buy 1 copy of the book and receive:

- Opportunity to send me a personalized email with one of the top issues that you need help with in your manufacturing or operations work.

- 50% discount for your first month of subscription to NewtoPro Manager AI application

- Link to a free download of "The Art of Empowering Questions" guide

A GROWTH DISTRIBUTER

Buy 10 and more copies of the book and I receive following:

-Are you an executive who wants to invest in your team member's growth from someone who spent two decades in Ops and manufacturing?

- Free first month of subscription to NewtoPro Manager AI application

-You will receive an option to book a 30-minute free introductory virtual session with me and your team.

A New Way For Manufacturing Folks To

Grow Faster Than Other 90%

And Free Yourself From The Clutches of Boring Manufacturing

I was a non-confident kid.

(and would never imagine I'd lead the teams for hundreds and thousands)Someone who even would be scared to call a store to ask a question.My dream job was to become a coding programmer so I could work alone and not communicate with other people.Sometimes I try to think of where this fear would come from.While I have a few ideas, the main one that comes to my mind is:

When I was a kid I avoided interaction with other kids, as I was wearing clothes given by our neighbors, friends of the family, etc. (see the picture below)

In some cases, those clothes and shoes were so large that, it was hard to move around.That fear pushed me away from my classmates, and from some of my friends, and I became an isolated, nerdy "the best inthe class" from all the subjects type of guy (I am talking about the period when I was 10-14 years old).And guess what?This challenge helped me to develop my greatest asset.Stick with the game-changing story, you've been searching for.In addition to everything above, my family moved to 3 different places when I was 10-14 years old (during one of the most complicated age groups).This meant 3 different neighborhoods, and 3 different changes in just four years.Mind you, back in 1992 we didn't have the luxury of Zoom, WhatsApp, the Internet, or video games to stay in touch remotely. Moreover - my family could barely afford food on the table.And so, I was always playing "the new kid in the classroom" game and had to learn how to manage it.Looking back, I think all the hardships in those years helped me to develop these two traits that I wouldn't trade for the world.Those two skills would help me put food on the table, buy a home, and a car, move to a better country, make a 6-digit income, and invest in my future.What are those?

Confidence and resilience.

Let me explain.Of course education matters. It might be the first thing your new employer asks.

But education alone is NOT enough.Sure knowing leadership tools and strategies matters. It will help you to navigate the technical parts of your leadership role. But these skills alone are NOT enough.So if you're a new manager or someone who feels stuck or overwhelmed - I got you, as I've been there, and have gone through that pain.In fact, I have grown from operator to Senior Director twice in two different countries in just 7 years.I have learned the hard way how to overcome the feeling of hesitation to hold your team members accountable.How demotivating is it to deal with different issues every single day, like there is no tomorrow.But the truth is - it doesn't have to be that way.But Hayk, what should we do then? - You'd ask.Well, glad you asked.There are three ways I can help.(Also feel free to find me on LinkedIn and say Hello) - >>>Hayk's LinkedIn profile

Freeway

The longest and the slowest solution

Every Saturday you will receive an email from me with actionable advice and tips on how to make you a more knowledgeable and better leader.How to convert your team members from "I don't know how Boss" to "Let me figure it out and get back to you ASAP".Here is the link to join the list of growing and successful leaders:>>>Lean Leader Growth weekly Newsletter

The theoretical way

By reading my eBook and paper copy book

Learn the tricks, secrets, and strategies that I compile in a book format for you, so you can grow faster than the other 90%. Almost 2 decades of my experience packed in 1.5-2 hours of reading time.To pre-order and later order your eBook follow the links below:>>>Lean Leader Formula - PeopleOn Amazon - >>>Lean Leader Formula - PeoplePapercopy will become available for you in Q1 2025.

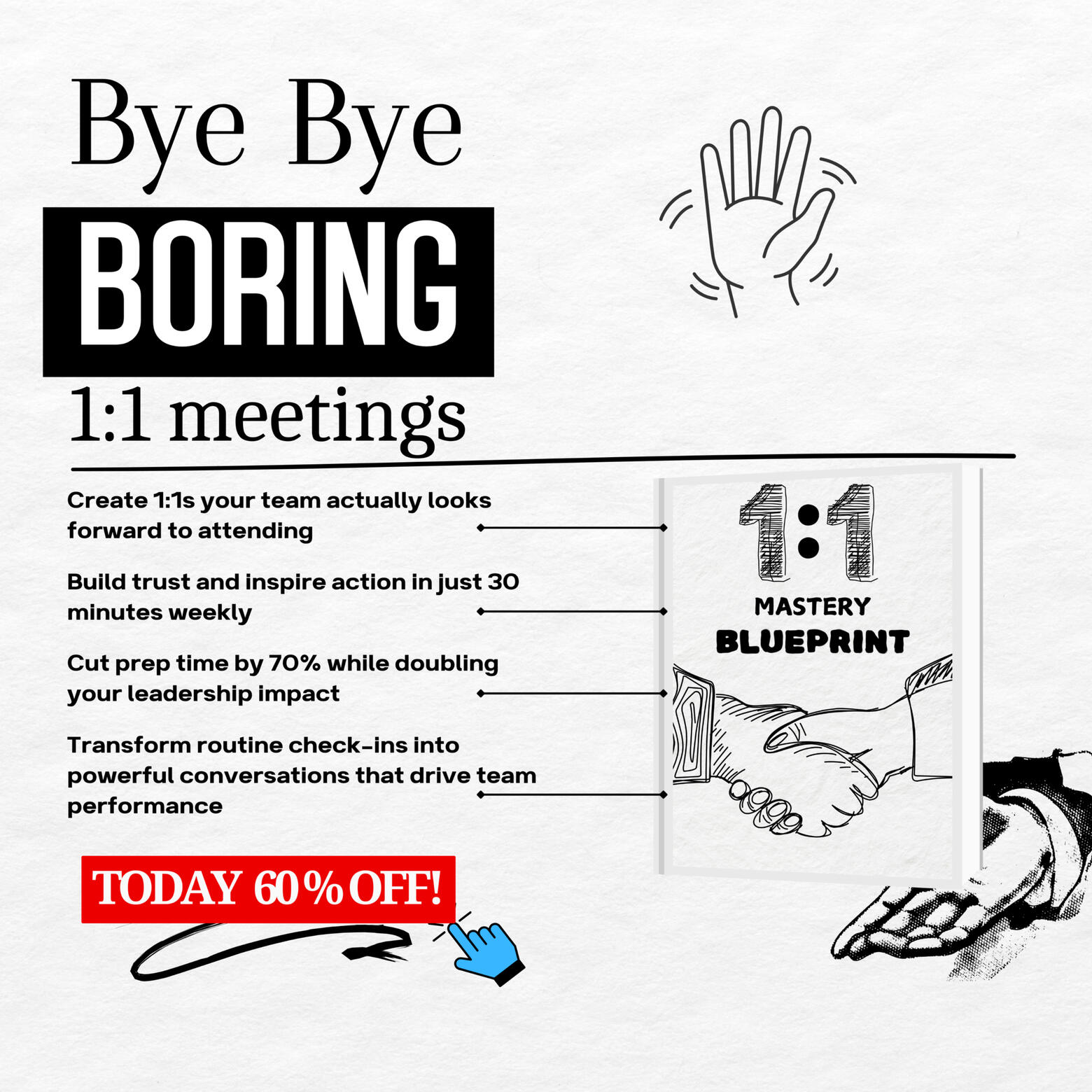

Individual 1:1 support

The fastest and most efficient way

Full and individual attention to your pain points, weekly or bi-weekly (yours to choose) coaching video calls with hands-on feedback, suggestions, and solutions.If you're interested in finding out more click the below link or book a free 15-minute discovery call.>>>Free Discovery CallThe link for learning more about 1:1 coaching sessions: >>>Coach Me

Whichever option you select, I'll show you how to remove your hesitation and gain confidence.We will master your resilience skills and make you unbeatable in the workplace.This is the only product and service, that will take you from "NO clue to how to manage people"...To confidently manage, delegate, drive, and motivate your small or large teams in manufacturing and operations.And the only thing we need...Your commitmentYour journey is not about a one-day win.It's about proving to yourself, that you've changed from the fragile to the confident leader or contributor.It's about transformation, that will leave you surprised when you look back and realize how much you've changed.So if you're ready to start your transformation journey - select the option you want to start with and enjoy the ride.Cheers to your success!!

You May Be One Book Away From Transforming

Your Approach to Growth Overnight

in Manufacturing and Not Only

It's time for you to find out how you can learn to convert your struggles with your team, processes, and equipment into your own success story.Sounds too good to be true?Well, bear with me to hear this real-world example:Let me explain how this broke, a 25-year-old used this unique PPE (People, Process, Equipment ) method to get promoted every 2 years and feel valued.5x his income to multiply 6-digit numbers.And publish his first book.Here’s how the story starts.

It’s 2007 in Armenia, which is a small, economically unstable post-Soviet Union country.With 27% of unemployment, finding a job was about as promising as finding a needle in the haystack. (Even though he had a Master’s degree in Engineering).The fact that the guy was engaged helped and made the situation even more stressful.So what do you think a broke, engaged 25-year-old would do?Steal something, gamble?

No!He took the first possible job he could find - a line operator in a chocolate factory, with a “whooping” $200 salary. (If you think a day, you’re mistaken).Yeah - $200 MONTHLY salary.And he thought “Well, I have a Master’s degree so it will take me no time to grow to a manager position, right?”

WRONG.Nobody gave a shit about his degree and knowledge of biomedical engineering.But this guy was committed to playing a long game.So he started to learn the machines and the processes.

Soon enough, he became the best operator in the factory.But the problem was, nobody considered him as the next leader or manager.This is when he decided to focus on people, emotions, and behavior.And guess what?Some Senior leaders started to approach him and show some interest.Long story short - our friend started to receive promotion after promotion.Until he reached the Plant’s Senior Ops Director position, with a responsibility to manage 2500 people. (I know it sounds crazy).With 7X income if compared to the line operator (in just 7 years).

(And believe me $1500 in 2014, in Armenia was a very large amount of money).So you’d think this is the happy ending of this story.Well, not exactly.This guy thought that there was still something missing.He decided to start everything from scratch by immigrating to…

… Canada.Where he didn’t have any close friends or family members.Why?

Well, he became a father and wanted to raise his kids in the country away from the wars and political turmoils.

So the guy and his family immigrated to Canada in 2017.If you are not familiar with the Canadian job market - let me describe it this way.There is 0 trust in anyone who comes from another country, and all the hiring managers ask is:

“WHAT IS YOUR CANADIAN EXPERIENCE” - like the job tasks are different in Europe from Canada.So he had to start from scratch.While I won’t go through this journey in detail (maybe this could be another story), but want to share with you this - in less than 7 years, this guy grew from shift line leader to Senior Director, managing around $200 million in revenue factory.This is while earning multiple-6-digit income.And being recognized as the best leader(twice).Buy a home, an investment property…

(Have you seen house prices in GTA - they are insanely high).Who is this guy?

Well, that’s me - Hayk.But why are you telling me all this?Because, If you are in manufacturing or operations, you have a rare chance to learn about my 18 years of experience in just 1.5-2 hours.If you struggle with your manager, peers, or team members…

If you struggle fighting fires every day like you are in a warzone…

If you don’t know what is your purpose, and why you’re not being valued…Then this message is for you.Because today you’ll learn how to stand out from the crowd with the simple Lean Leader Formula in just 1.5-2 hours of reading time (each book).You will learn everything you need to know to build the right relationship with your manager and team members.Find out methods, that nobody wants to teach you, but which are going to help you to stand out from the crowd of your peers.You see, my struggles to grow have helped me to understand this simple truth:

Lean manufacturing gurus and coaches are not going to save you.

Why?Well, because having a green or black belt in lean Six Sigma is not your growth ticket in people's relationships.Everything starts and flows with people.But Hayk, why should I give a shit to your book?Glad you asked.Because we’re drowning in lean consultants, coaches, and other lean gurus ocean.These guys come and suggest a quick and magical solution to your problems.They would say that increasing your efficiency will help you to grow fast.BS.Maybe for one single day, or a maximum of a week.Genuine people relationship - this is what going to help you to stand out from everyone else.You need to master People relationships first because that is how you build trust, transparency, and genuine connections.This is the first kind of investment you will need to make in your own growth.7 years ago I started from scratch in a totally strange country, and culture with totally strange people.My formula helped me to deliver results (and fast).It delivers results even:You have 30 minutes a day.You learn slowly.You just started in operations or manufacturing.You don’t know where to start.Or you have lots of folks to compete with.Because you don’t have to have a green or black belt or have graduated from Oxford or Cambridge to get others to trust you, support you, and help you to grow and succeed.Using this book you can:Learn where you stand in your journey.How to understand what your manager wants.How to understand what your team members want.Know your team.What leadership styles you should employ?How to build a strong team.How to communicate and solve different conflicts.In just 2 hours.

Of course, you could find this information from someone else, or maybe search online too, but…I’ve spent 18 years learning, working, struggling, succeeding, and growing in this field.I’ve read dozens of books, courses, and articles to learn the theory and apply the practice.I spent countless hours putting all this knowledge together, and adjusting it while I was working in a very dynamic position.I managed a team size from 15 to 2500 people.Managed budgets from $200K to $12000000.Run factories with more than $200000000 revenue.And every key position I held - I excelled there.Multiple “Oscars”, recognitions, letters, and happy managers and senior leaders.

As a matter of fact, in most cases, I’ve grown without applying to any of the growth positions.So I engineered a formula that brings simple tactics into trust, genuine connections, and transparency. The formula transforms you from the leader who has fear to delegate and execute, to the leader who is respected and has authority in his/her field.Now you can spend 8 years and $10,000+ like I did…ORYou can get the Lean Leader Formula -People ebook and later the paper copy that condenses all of this information into a 2 hours reading.What else?You will have the option to ask me questions via email in the first month of the purchase, and I will make sure to reply to you personally.

Here are just 7 great things you’ll discover:More than 10 people performance, evaluation, training, and lean practice-related tools for free (more than $900 value)

The proven way to understand what your manager wants and how to interpret it

The proven way to understand what your team members want and how to align with your manager’s and organization’s goalsWhich leadership style you should employ based on the situation you’re in

How to build a strong team, which knows what to do and which will support you in your own growth

The secret of communication (verbal, written, even body language)

How to resolve conflictsAnd much more…This book is like having an expert coach in your pocket or laptop.

HERE WHAT PEOPLE SAY ABOUT MY LEADERSHIP

AND FOR NEXT 4 WEEKS only…

You can get this eBook for only $9.9.Why is it only $9.9?Because I don’t believe in ripping people off with $1,000 cohorts that don’t deliver results.I don’t believe in Green, Black, or Purple belt online courses for $197, without any hands-on and practical actions.Everyone in manufacturing should be able to have a chance for growth.Buy the Lean Leader Formula - People, ebook today.

And get the knowledge that is cheaper than a pizza in price, but…Can deliver 100x Return on your investment, if used right.

If you buy the ebook, you’ll also get the physical copy with my handwritten signature, when the paper copy is released.

CHAPTERS (WHAT’S INSIDE)Chapter 1

Revealing the formula.Chapter 2

Assess Your Starting PointChapter 3’

Team building and employee motivationChapter 4

Communications(All types)Chapter 5

Conflict resolutionChapter 6

Training and skill development

Frequently Asked Questions

Who is this book intended for?

This book is tailored for line operators and junior and mid-level managers in manufacturing who aspire to accelerate their growth beyond the traditional timelines. If you're eager to become a better leader and streamline team processes, this is for you.

How is this different from other manufacturing leadership books?

Unlike generic leadership books, this focuses on the unique challenges of manufacturing, using the PPE (People, Process, Equipment) framework. It blends practical advice with real-world examples to give you actionable strategies.

I’ve read similar books before. What new value will I gain from this one?

This book offers a firsthand account of my rapid career progression within manufacturing, sharing strategies that helped me achieve Director-level positions twice in record time compared with the industry standard.

Do I need to read the entire series to see the results?

Not necessarily. Each book in the PPE series stands alone, focusing on a specific pillar of success. This first book, “People,” offers immediate tools to improve team dynamics and leadership skills. I’d say this is the most important part of your growth.

If you master the People portion, the rest will come easier.

What if I don’t agree with some strategies in the book?

Every organization and leader is unique. The strategies are adaptable to suit varying situations. Experiment with what resonates, and tweak as necessary.

Also, you can reach me at [email protected]

I will help you as much as I can.

Will this book help me get promoted faster?

While promotions are not guaranteed, applying the principles in this book will position you as a high-performing leader, making you a strong candidate for advancement.

What if my company lacks growth opportunities?

The strategies also equip you to identify and pursue external opportunities, ensuring your career growth isn’t limited by organizational constraints.

I’m already overwhelmed with my current workload. How can I find time to apply these strategies?

The book emphasizes gradual implementation. By prioritizing small, impactful changes, you’ll see results without additional burnout.

Consume chapter by chapter, and implement gradually.

What sacrifices will I need to make to grow as fast as you did?

It was not a pinky-and-rosy journey for me and to be upfront with you, you will need to put in hours and reps to kick off the journey and create momentum.

And yes - you will need to step out of your comfort zone.

It’s about making strategic sacrifices for exponential gains.

What if I struggle to implement the book’s advice?

The book includes practical examples and exercises to guide you. Plus, you can revisit sections as your understanding deepens.

In addition to it, let me know where you struggle by reaching out at [email protected]

Does the book address leadership challenges in a multicultural workplace?

Yes. It draws on my experience managing diverse teams, offering insights on communication and team building across cultural lines.

I think you’d agree that the North American job market is one of the most multicultural markets, due to the high rate of immigration. Multicultural workplace brings some challenges, but also brings a lot of advantages too.

How long will it take to see results after applying these strategies?

Results depend on your effort and environment. Some tools can improve team morale immediately, while leadership growth is a longer-term journey.

Is this book applicable to industries outside of manufacturing?

While focused on manufacturing, many principles, like team motivation, communication, and conflict resolution, are transferable to other industries.

Can someone without leadership experience benefit from this book?

Absolutely. It’s an excellent resource for those aspiring to leadership roles, offering foundational skills to prepare for future opportunities.